Why Mining, Port, and Construction Fleets Need RECODA’s Triple-Shield Defense

When a single camera failure halts a $250,000 haul truck at a Chilean copper mine, the true cost isn’t just the $300 replacement part. It’s $18,000/hour in lost productivity — and 73% of these failures trace to one culprit: water and corrosion.

Shockingly, 68% of cameras branded “IP67 waterproof” fail within 6 months in environments like:

Ports: Salt spray corrodes lens seals

Mines: Acidic mud clogs drainage ports

Construction: 1500 PSI pressure washers blast water into housings

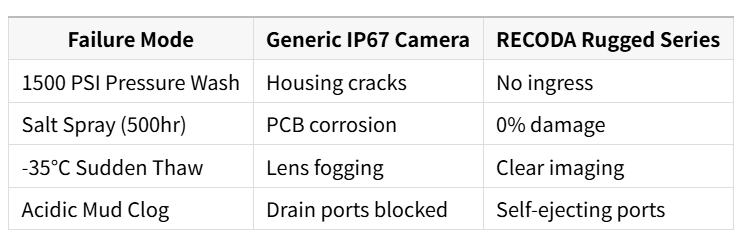

The problem? IP67 is a lab fantasy — it tests static immersion, not real-world abuse.

Engineered for law enforcement extremes and hardened for industrial warfare, our cameras deploy three patented shields:

Problem: Generic seals deform at 500 PSI, letting water invade PCBs.

RECODA’s Fix: Laser-welded titanium housings + spring-loaded multi-stage seals.

Proven: Survives daily mine decontamination sprays (tested at 1580 PSI).

Problem: Salt/acid eats aluminum housings; 42% fail at solder points.

RECODA’s Fix:

316L Surgical Stainless Steel Shells

Nano-Ceramic Coatings (repels chemical sludge)

Gold-Plated Circuit Boards

Proven: 0% corrosion after 500hr salt-fog testing (ASTM B117).

Problem: Rapid -35°C→65°C shifts cause internal fogging.

RECODA’s Fix:

Vacuum-sealed optics chambers

Phase-change thermal buffer gel

Proven: Crystal-clear imaging during Siberian winter-to-summer transitions.

*Australian Iron Ore Hauler (120-Truck Fleet)*

Old "IP67" Cameras: Failed every 4 months. Corrosion shorted CAN buses, causing $8,200/truck in electrical damage annually.

RECODA Solution:

36+ months continuous operation

Zero fogging or corrosion failures

$284,000 saved in Year 1 (parts + downtime)

“RECODA cameras survived acid washes that melted our previous units. Their pressure seals are like bank vaults.”

— Maintenance Director, BHP Iron Ore Operations

Contact RECODA Industrial Solutions Team